- Keycapor

Table of Contents

I get DMs all the time asking, “How exactly is an Artisan Keycap born?” So today, I’m not going to gatekeep. I’m going to break down our entire process using this Charizard Pokémon Keycap as an example.Whether you are a hobbyist looking to start or just curious about why these tiny caps cost what they do, this guide is for you.

Basically, the workflow is: 3D modeling -> resin printing -> hand-painting -> casting -> Polishing.

Step 1: Create a 3D Model that Fits the Keycap Profile

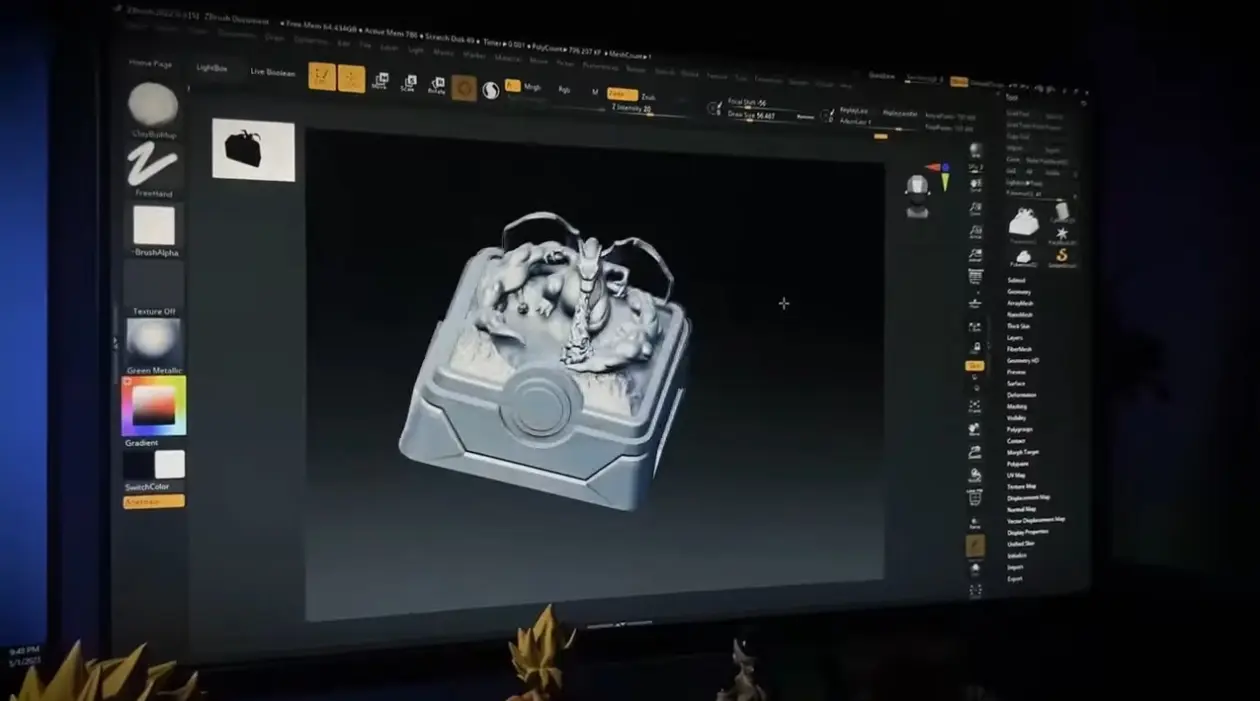

We use digital sculpting software to design the character and ensure it fits inside a keyboard switch.

We begin by sculpting the character using 3D software such as ZBrush or Blender.

In this project, we designed a fierce Charizard, carefully balancing its pose, proportions, and details.

Because this sculpture will eventually sit on a keycap, every millimeter matters.

It has to look powerful — but it must still feel comfortable when pressed.

Craftsman’s note:

Details are decided here. Wing textures, facial expression, and posture must be perfected at this stage. What isn’t sculpted now cannot be fixed la

Step 2: Print the Model Using an SLA Resin Printer

We print the digital model using a high-resolution liquid resin printer to capture the fine details.

Once the modeling is done, we print it using an SLA/DLP resin printer. Standard filament (FDM) printers just don’t have the precision to reproduce the tiny details we sculpted in the software.

Post-Processing: After printing, don’t forget to wash it with alcohol and cure it a second time in a UV chamber to ensure the model reaches maximum hardness.

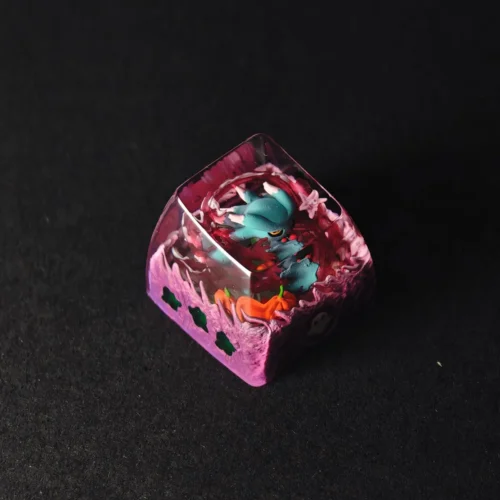

Step 3: Paint the Miniature with Thin Layers of Acrylic

We paint the white model by hand using micro-brushes and acrylic paint thinned with water.

Priming: First, we spray a thin layer of grey primer (surfacer). This gives the slick resin a “tooth” for the paint to stick to.

The Paint Technique (Crucial Detail): We use acrylic model paints. Never use paint straight out of the bottle. It is too thick and will hide the details. You must thin the paint with water until it has the consistency of skim milk.

Application: Using an ultra-fine detail brush (size 000), we apply 3–4 very thin layers rather than one thick coat. We start with the orange skin, then the teal wings, and finally, the eyes.

The Result: When you paint thin layers, the surface remains smooth. When you dot the eyes, the figure truly comes alive.

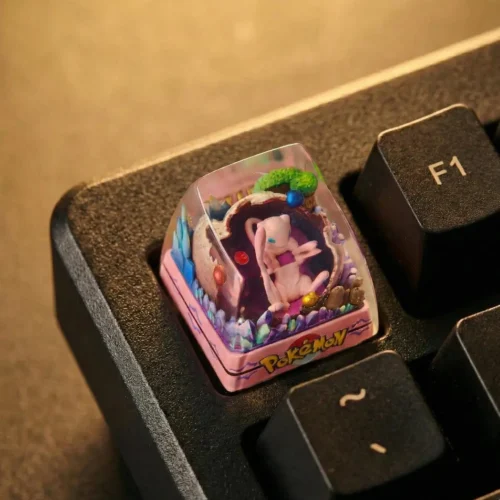

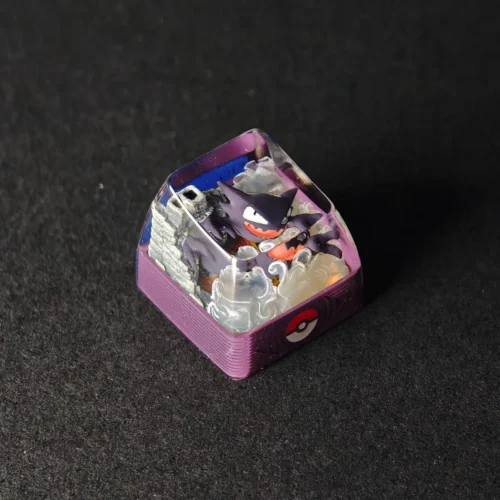

Step 4: Mix and Pour Epoxy Resin into the Mold

We measure clear epoxy resin by weight and pour it slowly into a silicone mold to seal the painted model.

Placement: We glue the painted dragon onto the keycap base (in this case, a Pokéball base).

The Resin (Glue) Science: We use high-grade, non-yellowing Epoxy Resin.

- The Ratio: You must measure Part A and Part B by weight using a digital scale. If you are off by even 0.1g, the resin will not cure and will remain sticky forever.

- The Mix: Stir slowly. If you whip it like eggs, you will add millions of bubbles.

Pouring: We slowly pour the mixed resin down the side of the silicone mold until it covers the model. Pouring slowly prevents trapping big air pockets under the dragon’s arms or wings.

Step 5: Cure the Resin in a Pressure Pot to Remove Bubbles

We place the wet mold into a pressure pot at 50 PSI for 24 hours to force air bubbles out of the resin.

The Problem: Even if you pour carefully, there are microscopic bubbles in the resin that make it look cloudy or fizzy.

The Solution: Immediately after pouring, the mold must go into a Pressure Pot.

How it Works: We pressurize the tank to 50 PSI and leave it for 24 hours. The pressure compresses the air bubbles until they are so small they become invisible. This is the only way to get a bubble-free, glass-like finish.

Step 6: Sand and Polish the Keycap for Transparency

Fresh out of the mold, the keycap surface is matte and slightly rough. It needs one last touch.

Wet Sanding: We use sandpaper dipped in water. Never sand dry. Dry sanding creates heat that melts the resin and turns it white. Water keeps it cool and smooth.

The Grits: We work our way up: 800 -> 1000 -> 1500 -> 2000 grit.

Polishing: Finally, we use a polishing compound with a wool buffing wheel. As the wheel spins, the fog vanishes, and the Charizard inside becomes clearly visible, suspended in the crystal.

Final Thoughts

And there you have it—an Artisan Keycap is born!

We took a pile of resin and paint and turned it into a piece of art. Although the steps sound simple, every stage—from mixing the resin ratio correctly to thinning the paint—requires intense focus.

At Keycapor, we love this process of “slow work yielding fine detail.” I hope this tutorial clears up the mystery. If you want to jump in and try it yourself, feel free to reach out!

Go create your own world!

-

Lucario Pokémon Keycaps – Limited Edition

$60.00 – $120.00Price range: $60.00 through $120.00 Quick Shop -

Rated 5.00 out of 5(1)

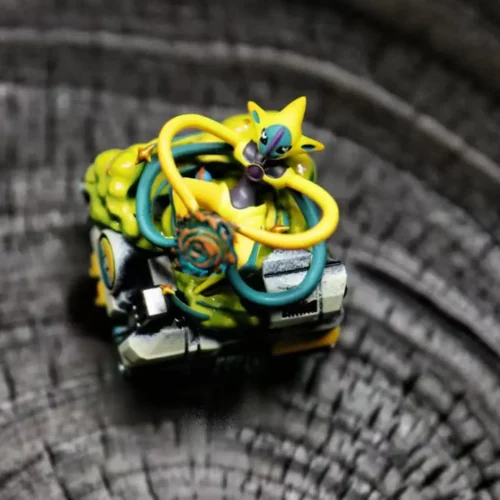

Deoxys Pokemon Keycap- Limited Edition

$60.00 – $120.00Price range: $60.00 through $120.00 Quick Shop

Frequently Asked Question

At minimum, you need a resin mixing setup, silicone molds, fine brushes, sanding paper, and proper safety gear.

Advanced tools like pressure pots improve results but are not required for learning.

Cloudiness is usually caused by moisture, incorrect resin ratios, or trapped air.

Always measure accurately and work in a dry environment for better clarity.

Yes, when properly cured.

They handle normal typing well, but should not be dropped or exposed to high heat or long-term direct sunlight.

Not strictly, but it significantly improves clarity.

Without one, small bubbles are harder to eliminate, especially in clear or translucent keycaps.

Surface scratches can be sanded and polished.

Internal bubbles or misalignment cannot be corrected once the resin has cured.

Rushing the process is the biggest issue.

Mixing resin too fast, pouring too quickly, or demolding early often leads to bubbles and surface defects. Slow, controlled steps matter more than speed.